When designing or repairing a plumbing system, selecting the right steel pipe nipple is crucial for ensuring durability, leakfree connections, and optimal performance. With various materials, sizes, and standards available, making the correct choice can be challenging. This guide will help you navigate the key factors to consider when choosing a steel pipe nipple for your plumbing needs.

- Material Selection: Carbon Steel vs. Stainless Steel

Steel pipe nipples come in different materials, each suited for specific environments:

Carbon Steel (ASTM A53/A106): Costeffective and strong, ideal for general plumbing, water supply, and lowpressure gas systems.

Stainless Steel (ASTM A312 304/316): Offers superior corrosion resistance, making it perfect for harsh environments, chemical transport, and foodgrade applications.

Industry Insight: Cangzhou Hongxin, a leading manufacturer of steel pipe fittings, produces highquality galvanized and black steel pipe nipples that meet ASTM standards, ensuring longlasting performance in plumbing systems.

- Thread Type and Standards

Proper threading ensures a secure connection:

NPT (National Pipe Thread): The most common in North America, tapered for a tight seal.

BSP (British Standard Pipe): Used in Europe and Asia, available in parallel (BSPP) and tapered (BSPT) variants.

Metric Threads: Required for certain international applications.

Expert Tip: Always verify thread compatibility before installation to avoid leaks.

- Size and Wall Thickness (Schedule Rating)

Schedule 40: Standard thickness for most plumbing applications.

Schedule 80: Thicker walls for highpressure systems.

Custom Lengths: Some suppliers, like Cangzhou Hongxin, offer customcut steel pipe nipples for specialized projects.

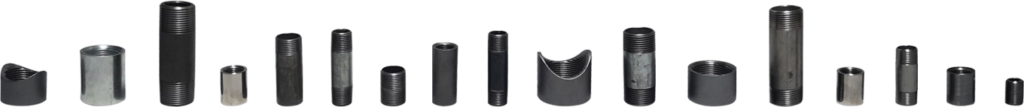

- Coating and Corrosion Protection

Galvanized Steel pipe nipple: Zinccoated for rust resistance in outdoor or wet environments.

Black Steel pipe nipple : Uncoated, best for indoor gas lines (requires proper sealing).

Stainless Steel pipe nipple: Naturally corrosionresistant, ideal for marine or chemical exposure.

- Pressure and Temperature Ratings

Always check:

Maximum PSI rating to ensure the nipple can handle system pressure.

Temperature limits if used in hot water or steam lines.

- Supplier Reliability and Certification

Choose a trusted manufacturer like Cangzhou Hongxin, which supplies ASTMcertified steel pipe nipples with strict quality control, ensuring compliance with international plumbing standards.

Final Recommendations

For residential plumbing, carbon steel (galvanized or black) Schedule 40 nipples are typically sufficient.

For industrial or corrosive environments, stainless steel (304 or 316) pipe nipple is the best choice.

Always match thread types and verify dimensions before purchasing.

By considering these factors, you can ensure a leakfree, efficient plumbing system with the right steel pipe nipple. For bulk orders or custom specifications, reputable suppliers like Cangzhou Hongxin pipe fittings CO.,LTD provide highquality solutions tailored to your project needs.