Threaded Steel Pipe Nipples: Sizes, Dimensions & Compatibility Chart

Threaded steel pipe nipples are essential components in plumbing, oil & gas, HVAC, and industrial piping systems. They provide secure, leak-proof connections between pipes, valves, and fittings. Choosing the right size, material, and thread type is critical for system integrity.

This guide covers:

Standard sizes & dimensions (NPT, BSP, metric)

Material compatibility (carbon steel, stainless, galvanized)

Pressure ratings & temperature limits

Thread standards (NPT vs. BSP vs. metric)

Downloadable sizing chart

Standard Threaded Steel Pipe Nipple Sizes

Threaded pipe nipples come in various lengths and diameters, categorized by:

A. Nominal Pipe Size (NPS)

| NPS (inches) |

Actuall OD (inches) |

Threads per INCH(TPI) |

| 1/8 | 0.405 | 27 |

| 1/4 | 0.54 | 18 |

| 3/8 | 0.675 | 18 |

| 1/2 | 0.84 | 14 |

| 3/4 | 1.05 | 14 |

| 1 | 1.315 | 11.5 |

| 1 1/2 | 1.9 | 11.5 |

| 2 | 2.375 | 11.5 |

B. Common Lengths

Close nipple (shortest, fully threaded)

Short nipple (1–2″ longer than close)

Long nipple (custom lengths up to 12″)

Thread Standards & Compatibility

A. NPT (National Pipe Thread) – USA Standard

Tapered threads (seal via thread deformation)

Common in North America

Requires thread sealant (Teflon tape, pipe dope)

B. BSP (British Standard Pipe) – Global Use

BSPT (tapered) & BSPP (parallel)

Common in Europe, Asia, Australia

Not interchangeable with NPT

C. Metric Threads (ISO 228/7)

Used in machinery & automotive

M-style threads (e.g., M10, M12)

⚠ Warning: Mixing NPT and BSP can cause leaks! Always verify thread type.

Material Selection Guide

Carbon steel

Stainless steel 304 & 304L

Stainless steel 316 & 316L

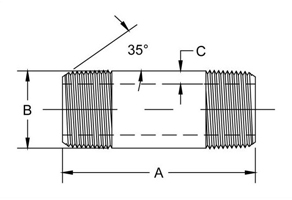

The stainless steel pipe nipple size chart

Material: ASTM A312, Type 304/304L or 316/316L ;Welded or Seamless

Threads: ANSI/ASME B 1.20.1

| Pipe Size |

B | A. Length | ||||||||||||||||

| Pipe O.D. |

Close | Space | ||||||||||||||||

| 1/8 | 0.405 | 3/4 | 1 1/2 | 2 | 2 1/2 | 3 | 3 1/2 | 4 | 4 1/4 | 5 | 5 1/2 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| 1/4 | 0.54 | 7/8 | 1 1/2 | 2 | 2 1/2 | 3 | 3 1/2 | 4 | 4 1/4 | 5 | 5 1/2 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| 3/8 | 0.675 | 1 | 1 1/2 | 2 | 2 1/2 | 3 | 3 1/2 | 4 | 4 1/4 | 5 | 5 1/2 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| 1/2 | 0.84 | 1 1/8 | 1 1/2 | 2 | 2 1/2 | 3 | 3 1/2 | 4 | 4 1/4 | 5 | 5 1/2 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| 3/4 | 1.05 | 1 3/8 | 1 1/2 | 2 | 2 1/2 | 3 | 3 1/2 | 4 | 4 1/4 | 5 | 5 1/2 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| 1 | 1.315 | 1 1/2 | 2 | 2 1/2 | 3 | 3 1/2 | 4 | 4 1/4 | 5 | 5 1/2 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |

| 1 1/4 | 1.66 | 1 5/8 | 2 | 2 1/2 | 3 | 3 1/2 | 4 | 4 1/4 | 5 | 5 1/2 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |

| 1 1/2 | 1.9 | 1 3/4 | 2 | 2 1/2 | 3 | 3 1/2 | 4 | 4 1/4 | 5 | 5 1/2 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |

| 2 | 2.375 | 2 | 2 1/2 | 3 | 3 1/2 | 4 | 4 1/4 | 5 | 5 1/2 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | ||

| 2 1/2 | 2.875 | 2 1/2 | 3 | 3 1/2 | 4 | 4 1/4 | 5 | 5 1/2 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |||

| 3 | 3.5 | 2 5/8 | 3 | 3 1/2 | 4 | 4 1/4 | 5 | 5 1/2 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |||

| 4 | 4.5 | 2 7/8 | 4 | 4 1/4 | 5 | 5 1/2 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |||||

| 5 | 5.563 | 3 | 4 1/4 | 5 | 5 1/2 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | ||||||

| 6 | 6.625 | 3 1/8 | 4 1/4 | 5 | 5 1/2 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | ||||||

| 8 | 8.625 | 3 1/2 | 4 1/4 | 5 | 5 1/2 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | ||||||

Pressure & Temperature Ratings

Schedule 40: Standard for general plumbing (300–1000 PSI)

Schedule 80: High-pressure industrial use (1000–3000 PSI)

Temperature Limits:

Carbon steel: Up to 500°F (260°C)

Stainless steel: Up to 800°F (427°C)

How to Measure a Threaded Nipple

1. Determine Nominal Pipe Size (NPS) – Measure outer diameter (OD).

2. Check Thread Pitch– Use a thread gauge (TPI for NPT, pitch for metric).

3. Verify Length – Measure from end to end (including threads).

📌 Pro Tip: Always use a thread sealant (Teflon tape for NPT, Loctite for BSPP).

Common Applications

✔ Plumbing – Connecting water lines, valves

✔ Oil & Gas – High-pressure pipe joints

✔ HVAC – Refrigerant & steam lines

✔ Industrial Machinery** – Hydraulic fittings

Where to Buy Quality Threaded Nipples

– ASTM A53 (Carbon steel)

– ASTM A312 (Stainless steel)

– API 5L (Oil & gas certified)

Final Thoughts

Thread type (NPT/BSP/Metric)

Material (carbon/stainless/galvanized)

Pressure & temperature requirements

#Piping #Plumbing #OilAndGas #HVAC #Engineering #IndustrialMaintenance