What is a King Nipple?

The Essential PipetoHose Transition Fitting

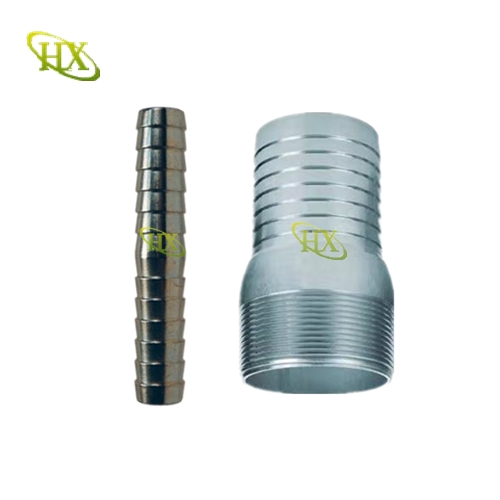

A King Nipple (also called KC Nipple or Combination Nipple) is a specialized industrial fitting that seamlessly bridges femalethreaded pipes and flexible hoses. Its unique dualended design solves connection challenges in liquid/gas transfer systems where space and compatibility matter.

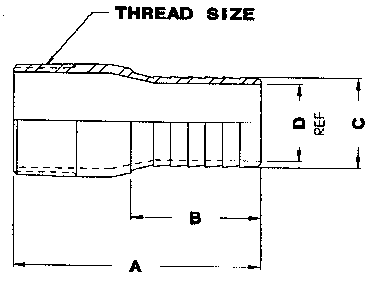

| Pipe Size | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 |

| A | 3.125 | 3.375 | 3.500 | 3.500 | 4.250 | 4.250 | 5.375 | 5.875 | 7.000 |

| C | 0.645 | 0.845 | 1.075 | 1.405 | 1.640 | 2.095 | 2.505 | 3.100 | 4.060 |

Key Features & Design

DualFunction Ends:

Male NPT Thread: Screws into standard femalethreaded pipes, valves, or equipment.

Smooth Hose Shank: Barbfree surface for secure hose + clamp attachment.

No Hex Nut: Streamlined body prevents snagging in tight spaces.

Material Versatility:

| Material | Best For |

| Carbon Steel | Cost-effective plumbing, compressed air, oil/gas |

| 304 Stainless | Chemical/water systems, moderate corrosion resistance |

| 316 Stainless | Food processing, marine, high-corrosion environments |

Critical Specifications:

Sizes: 1/4″ to 12″ (Standard) • Customizable

Thread: NPT (National Pipe Taper) or BSPT

Pressure: ❌ Not for steam systems • Varies by material/clamp

1/2″ Dimensions: Length (A): 3.125″ • Thread OD (C): 0.645″

Why Choose a King Nipple?

- Simplified Connections

Replaces multiple fittings – one solution for pipetohose transitions.

- SpaceSaving Design

Hexless body fits flush in cramped areas (e.g., machinery, irrigation).

- Material Flexibility

Optimize cost (carbon steel) or corrosion resistance (stainless steel).

- LeakProof Performance

Precision threads + clampsecured hose ensure reliable seals.

Applications

| Applications | |

| Carbon Steel | Stainless Steel (304/316) |

| – Compressed air lines | – Chemical transfer |

| – Fuel/oil pipelines | – Food/pharma processing (316 only) |

| – Low-pressure hydraulics | – Marine/offshore equipment |

| – General construction | – Water treatment plants |

| ! Never Use For: Steam systems, thermal shock, or gas >150 PSI. | |

⚠️ Never Use For: Steam systems, thermal shock, or gas >150 PSI.

Installation Guide

- Threaded End: Apply Teflon tape → screw into female NPT or BSPT port.

- Hose End: Slide hose over shank → secure with two clamps.