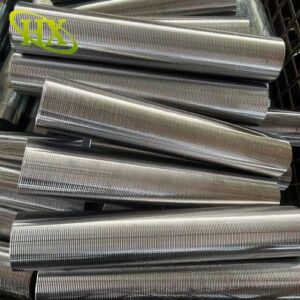

ASTM A 106 seamless steel pipe nipples China supplier,Oil & gas pipeline fittings

Introduction to Seamless Steel Pipe Nipples

Seamless steel pipe nipples are essential components in industrial, commercial, and residential piping systems. These short pipe connectors ensure leak-proof, high-pressure fluid and gas transfer in plumbing, oil & gas, chemical processing, and HVAC applications. Unlike welded nipples, seamless versions offer superior strength, corrosion resistance, and durability, making them ideal for demanding environments.

In this comprehensive guide, we’ll explore the benefits, manufacturing process, applications, and selection criteria for seamless steel pipe nipples. Whether you’re an engineer, contractor, or DIY enthusiast, this article will help you make an informed decision for your piping needs.

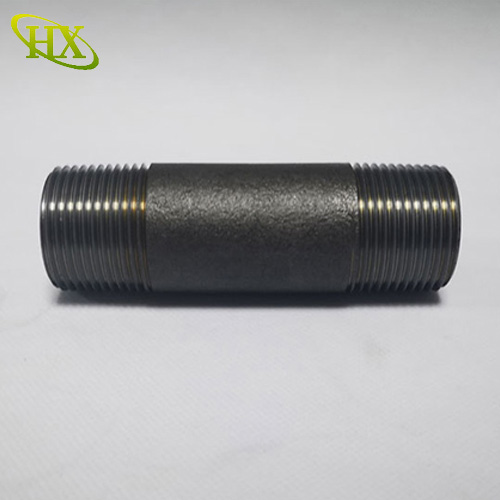

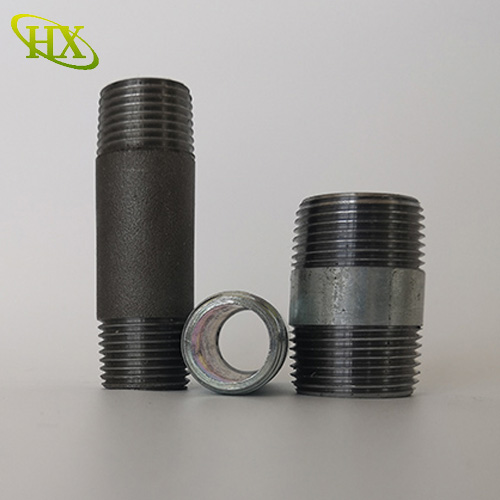

What is a Seamless Steel Pipe Nipple?

A seamless steel pipe nipple is a short length of pipe with male threads on both ends, used to connect two female-threaded pipes or fittings. Since it lacks welded seams, it provides:

Higher pressure resistance (ideal for hydraulic and steam systems)

Better corrosion resistance (no weak points from welding)

Smoother internal flow (reduced turbulence and friction loss)

Longer lifespan (resistant to cracking and fatigue)

These nipples come in various materials, including carbon steel, stainless steel (304/316), and alloy steel**, each suited for different industrial requirements.

Manufacturing Process of Seamless Steel Pipe Nipples

Seamless nipples are produced through hot extrusion or cold drawing, ensuring a uniform structure without weak joints. The key steps include:

1. Billet Heating – A solid steel billet is heated to high temperatures.

2. Piercing & Extrusion – A mandrel pierces the billet, forming a hollow tube.

3. Cold Drawing (Optional) – For precision sizing and smoother finishes.

4. Threading & Machining – Threads are cut to industry standards (NPT, BSP, metric).

5. Surface Treatment – Galvanizing, blackening, or polishing for corrosion protection.

This process ensures high dimensional accuracy, strength, and reliability compared to welded alternatives.

Key Advantages of Seamless Steel Pipe Nipples

1. Superior Strength & Pressure Resistance

Seamless construction eliminates weak points, making them ideal for high-pressure oil & gas pipelines, hydraulic systems, and steam lines.

2. Corrosion & Chemical Resistance

Stainless steel variants (304/316) resist rust, acids, and extreme temperatures, perfect for **chemical plants, marine applications, and food processing**.

3. Smooth Flow & Reduced Leak Risks

No internal seams mean less turbulence, friction loss, and leakage risks, improving efficiency in fluid transport systems.

4. Longer Service Life

With no welded joints to degrade, seamless nipples last longer, reducing maintenance costs.

5. Versatility in Applications

Used in:

Oil & Gas (drilling, pipelines)

Chemical Processing (acid transport)

HVAC & Plumbing (steam, water lines)

Power Plants (high-pressure steam)

Automotive & Aerospace (hydraulic systems)

How to Choose the Right Seamless Steel Pipe Nipple?

When selecting a seamless nipple, consider:

Material – Carbon steel (general use), stainless steel (corrosion resistance), alloy steel (high temp).

Size & Thread Type – NPT (US standard), BSP (UK/EU), or metric threads.

Pressure Rating – Ensure it meets system requirements (PSI/bar ratings).

Surface Treatment – Galvanized (rust-proof), black oxide (aesthetic), or polished (sanitary).

Certifications – ASTM, ASME, ANSI compliance for quality assurance.

Where to Buy High-Quality Seamless Steel Pipe Nipples?

Look for trusted manufacturers with:

ISO/ASTM/ASME certifications

Custom sizing & threading options

Competitive pricing & bulk discounts

Positive customer reviews

Final Thoughts: Why Choose Seamless Steel Pipe Nipples?

Seamless steel pipe nipples provide unmatched durability, safety, and efficiency in piping systems. Whether for industrial, commercial, or residential use, their leak-proof design, high-pressure tolerance, and corrosion resistance make them a superior choice over welded alternatives.

By selecting the right material, size, and certification, you can ensure long-term reliability and cost savings in your piping projects.