|

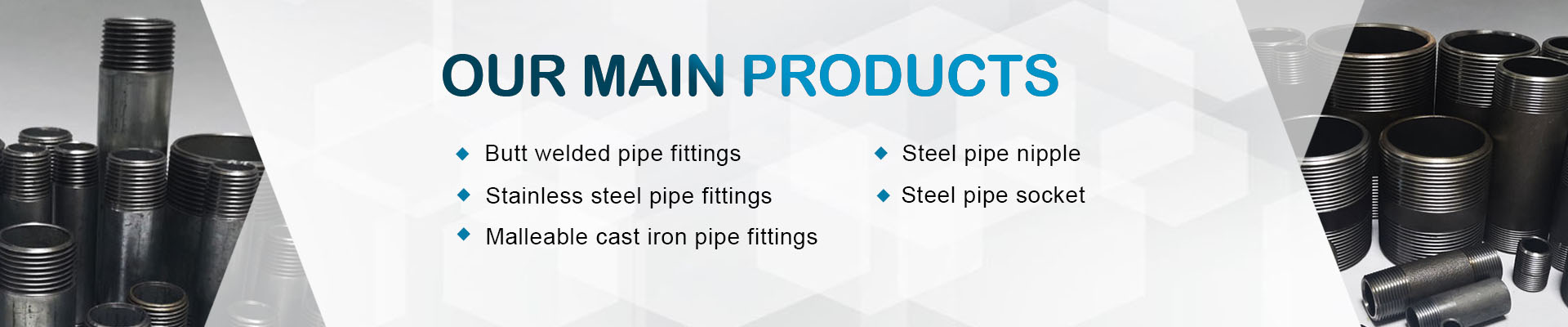

ELBOW 90° |

SIZE:1/2″~56″ |

|

ELBOW 45° |

SIZE:1/2″~56″ |

|

TEE |

SIZE:1/2″~56″ |

|

CAP |

SIZE:1/2″~56″ |

|

REDUCING TEE |

SIZE:1/2″~56″ |

|

CONCENTRIC REDUCER |

SIZE:1/2″~56″ |

|

ECCENTRIC REDUCER |

SIZE:1/2″~56″ |

Introduction to ButtWeld Carbon Steel Elbow

Buttweld carbon steel elbows are essential components in piping systems, designed to change the direction of fluid flow efficiently. These fittings are widely used in industries such as oil and gas, petrochemical, power generation, and water treatment due to their durability, highpressure resistance, and leakproof performance.

Cangzhou Hongxin is a leading manufacturer and supplier of highquality buttweld carbon steel elbows, offering products that meet international standards such as ANSI, ASME, ASTM, and DIN. Our elbows are precisionengineered to ensure seamless integration into various industrial applications.

What is a ButtWeld Carbon Steel Elbow?

A buttweld carbon steel elbow is a pipe fitting that allows for directional change in a piping system at specified angles, typically 45°, 90°, or 180°. The term “buttweld” refers to the welding method where the elbow is joined to the pipe by welding the beveled ends together, ensuring a strong and permanent connection.

Key Features of Cangzhou Hongxin’s ButtWeld Carbon Steel Elbows:

Material: Made from highquality carbon steel (ASTM A234 WPB, ASTM A105, etc.) for superior strength and corrosion resistance.

Types: Available in 45°, 90°, and 180° angles with short radius (SR) and long radius (LR) options.

Standards Compliance: Manufactured according to ASME B16.9, ANSI B16.28, MSSSP75, and DIN standards.

Pressure Rating: Suitable for highpressure and hightemperature applications.

Surface Treatment: Black painting, galvanization, or anticorrosion coatings available upon request.

Customization: Custom sizes, thicknesses, and material grades can be provided to meet specific project requirements.

Applications of ButtWeld Carbon Steel Elbows

Buttweld carbon steel elbows are widely used in industries where reliable and durable piping systems are crucial. Some common applications include:

- Oil & Gas Industry

Used in pipelines for crude oil, natural gas, and refined petroleum products.

Ensures smooth directional changes in highpressure transmission systems.

- Chemical & Petrochemical Plants

Resistant to corrosive fluids and high temperatures.

Ideal for acid, alkali, and solvent transportation systems.

- Power Generation

Used in steam pipelines, boiler systems, and cooling water circuits.

Withstands extreme thermal and mechanical stress.

- Water Treatment & Distribution

Ensures efficient water flow in municipal and industrial water supply networks.

Resistant to rust and scaling.

- Shipbuilding & Marine Applications

Used in fuel lines, ballast systems, and hydraulic piping.

Provides leakproof performance in harsh marine environments.

Advantages of Choosing Cangzhou Hongxin’s ButtWeld Carbon Steel Elbows

- Superior Quality & Durability

Our elbows are manufactured using premiumgrade carbon steel, ensuring longlasting performance even in extreme conditions.

- Precision Engineering

Strict quality control measures ensure dimensional accuracy, smooth internal surfaces, and optimal flow efficiency.

- Competitive Pricing

As a direct manufacturer, Cangzhou Hongxin offers costeffective solutions without compromising quality.

- Fast Delivery & Global Supply

With a wellestablished logistics network, we ensure timely delivery to clients worldwide.

- Custom Solutions

We provide tailored solutions based on customer specifications, including special sizes, materials, and coatings.

Types of ButtWeld Carbon Steel Elbows

- 45° Elbow

Used for moderate directional changes.

Reduces pressure drop and turbulence in the pipeline.

- 90° Elbow

The most common type, allowing perpendicular direction change.

Available in short radius (SR) and long radius (LR) variants.

- 180° Elbow (Return Bend)

Used for complete flow reversal.

Ideal for heating coils and heat exchanger systems.

- Short Radius (SR) vs. Long Radius (LR) Elbows

Short Radius (SR): Compact design, suitable for tight spaces.

Long Radius (LR): Smoother flow with reduced friction loss.

Manufacturing Process of ButtWeld Carbon Steel Elbows

At Cangzhou Hongxin, our manufacturing process includes:

- Material Selection: Highquality carbon steel billets are inspected for chemical composition.

- Hot Forming/ Cold Forming: Elbows are shaped using advanced bending techniques.

- Heat Treatment: Enhances mechanical properties and relieves internal stresses.

- Machining & Beveling: Ensures precise edge preparation for welding.

- Surface Treatment: Antirust coatings or galvanization applied if required.

- Quality Inspection: Hydrostatic testing, dimensional checks, and visual inspections.

- Packaging & Shipping: Secure packaging to prevent damage during transit.

Why Choose Cangzhou Hongxin?

ISOCertified Manufacturer: Ensures compliance with international quality standards.

Experienced Team: Over [X] years of expertise in pipe fittings production.

Comprehensive Testing: Each elbow undergoes rigorous quality checks.

CustomerCentric Approach: Dedicated support from inquiry to aftersales service.

Conclusion

Buttweld carbon steel elbows are critical components in industrial piping systems, ensuring efficient and safe fluid transportation. Cangzhou Hongxin provides topquality, durable, and costeffective solutions tailored to meet diverse industry needs.

For more details, customization options, or bulk orders, contact Cangzhou Hongxin today!

Optimized Keywords:

Buttweld carbon steel elbow, carbon steel pipe fittings, ASME B16.9 elbows, 90degree LR elbow, short radius elbow, carbon steel return bend, Cangzhou Hongxin, highpressure pipe fittings, industrial pipe elbows, ASTM A234 WPB elbows.

This wellstructured, keywordrich article enhances SEO visibility while providing valuable information to potential buyers. Let me know if you need any modifications!