When selecting steel pipe nipples for industrial applications, choosing the right material specification is crucial for performance, durability, and compliance with industry standards. Two of the most commonly used carbon steel pipe standards are ASTM A53 and ASTM A106. While both are widely used in piping systems, they have key differences in composition, mechanical properties, and intended applications.

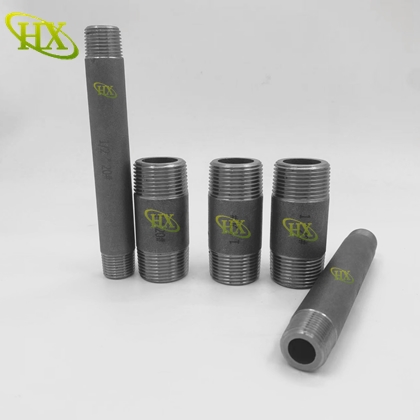

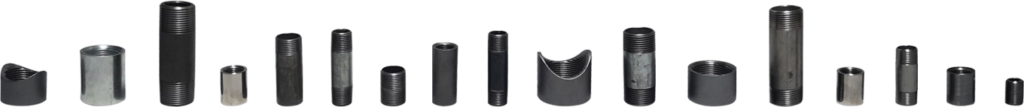

At Cangzhou Hongxin Steel Pipe Co., Ltd, we specialize in manufacturing highquality steel pipe nipples that meet ASTM A53 and A106 standards, ensuring reliability for various industrial uses. This article provides a detailed comparison to help you make an informed decision.

- Overview of ASTM A53 and ASTM A106 Steel Pipes

ASTM A53 Steel Pipe Nipples

Type: Carbon steel pipe, available in Grade A and Grade B.

Manufacturing Methods:

Type E (Electric Resistance Welded, ERW)

Type F (Furnace Butt Welded, FBW)

Type S (Seamless, SMLS)

Common Applications: Lowpressure plumbing, structural applications, and generalpurpose piping.

ASTM A106 Steel Pipe Nipples

Type: Seamless carbon steel pipe, available in Grade A, B, and C.

Manufacturing Method: Seamless (SMLS) only.

Common Applications: Hightemperature and highpressure services (e.g., boilers, refineries, power plants).

- Key Differences Between ASTM A53 and A106

| Property | ASTM A53 | ASTM A106 |

| Manufacturing | ERW, FBW, or Seamless | Seamless only |

| Grades Available | Grade A & B | Grade A, B, & C |

| Tensile Strength | 330 MPa (Grade B) | 415 MPa (Grade B) |

| Temperature Use | Up to 350°C (662°F) | Up to 450°C (842°F) |

| Pressure Rating | Lower pressure handling | Higher pressure handling |

| Common Uses | Plumbing, structural | Power plants, refineries |

Why ASTM A106 is Preferred for HighTemperature Applications?

Higher carbon content improves strength at elevated temperatures.

Seamless construction eliminates weak points, making it ideal for critical applications.

- Choosing the Right Pipe Nipple for Your Project

When to Use ASTM A53 Pipe Nipples?

Lowpressure water & gas systems

Structural supports & fencing

Generalpurpose industrial piping

When to Use ASTM A106 Pipe Nipples?

Highpressure steam & oil pipelines

Boilers & heat exchangers

Power generation & petrochemical plants

At Cangzhou Hongxin, we supply both ASTM A53 and A106 steel pipe nipples in various sizes, ensuring compliance with international standards.

- Why Choose Cangzhou Hongxin for Steel Pipe Nipples?

HighQuality Materials: Strict adherence to ASTM standards.

Custom Sizes & Specifications: Tailored solutions for industrial needs.

Competitive Pricing: Costeffective without compromising quality.

Global Export Experience: Trusted supplier for international clients.

Whether you need ASTM A53 or A106 pipe nipples, Cangzhou Hongxin provides reliable solutions for your piping systems.

Conclusion

Understanding the differences between ASTM A53 and A106 steel pipe nipples ensures optimal performance in your applications. While A53 is suitable for generalpurpose use, A106 excels in hightemperature and highpressure environments.

For highquality ASTMcompliant steel pipe nipples, contact Cangzhou Hongxin Pipe fitting Co., Ltd today!