Understanding Close Nipples in Piping Systems

A close nipple (also called a “running nipple”) is a short, fully threaded pipe fitting used to connect two femalethreaded components with minimal spacing. Unlike standard pipe nipples, a close nipple has no unthreaded shoulder—threads run from end to end, allowing for a tight, compact connection.

Why Use a Close Nipple?

Close nipples are essential in piping systems where:

Space is limited – Ideal for tight installations where longer nipples won’t fit.

A flush connection is needed – Ensures minimal gap between fittings.

Highpressure sealing is required – Threaded ends provide a secure, leakresistant joint.

Material Options:

Carbon Steel (Black/Galvanized) – For general industrial use.

Stainless Steel – Corrosionresistant for chemical & foodgrade applications.

Brass – Used in plumbing & lowpressure systems.

How long is a Close Nipple?

A close nipple is typically as short as possible, with no unthreaded portion between the two threaded ends. Its length is effectively enough to allow for the full threading on each side, bringing the two connected fittings as close as possible.

The exact length of a close nipple varies depending on the pipe size (diameter). It is generally very short, often between 1 to 1.5 inches (2.5 to 3.8 cm) for diameters like 1/2 inch or 3/4 close nipple. The length may increase slightly For larger diameters to allow for full threading. However, this increase will be minimal.

Plumbing nipples are specified by their diameter rather than their exact length, emphasizing the close connection rather than a precise measurement.

Close Nipple Size Chart – Diameter & Thread Specifications

Below is a standard close nipple size chart with dimensions based on NPT (National Pipe Thread) standards:

| Nominal Pipe Size (NPS) | Outer Diameter (OD) | Threads Per Inch (TPI) | Approx. Length (Fully Threaded) |

| 1/8 | 0.405 | 27 | 0.5 |

| 1/4 | 0.54 | 18 | 0.5 |

| 3/8 | 0.675 | 18 | 0.6 |

| 1/2 | 0.84 | 14 | 0.8 |

| 3/4 | 1.05 | 14 | 0.9 |

| 1 | 1.315 | 11.5 | 1.1 |

| 1 1/2 | 1.9 | 11.5 | 1.4 |

| 2 | 2.375 | 11.5 | 1.6 |

Note: Sizes beyond 2″ are available but less common. Custom lengths & threads (BSPT, Metric) can be supplied.

Common Applications of Close Nipples

Plumbing Systems – Connects valves, elbows, and tees in tight spaces.

Hydraulic & Pneumatic Lines – Ensures compact, highpressure fittings.

Oil & Gas Pipelines – Used in pumps, compressors, and flange adapters.

HVAC & Fire Protection – Joins sprinkler heads and ductwork fittings.

Industrial Machinery – Provides short, rigid connections in equipment.

How to Install a Close Nipple?

- Apply thread sealant (Teflon tape or pipe dope) to prevent leaks.

- Screw into the first female fitting by hand to avoid crossthreading.

- Use a pipe wrench to tighten securely (avoid overtightening).

- Connect the second fitting and tighten for a sealed joint.

Where to Buy HighQuality Close Nipples?

As a leading pipe fittings supplier, we provide:

ASTM/ASMEcompliant close nipples

Carbon steel, stainless steel & brass options

Custom sizes & threading (NPT, BSPT, Metric)

Bulk order discounts & fast global shipping

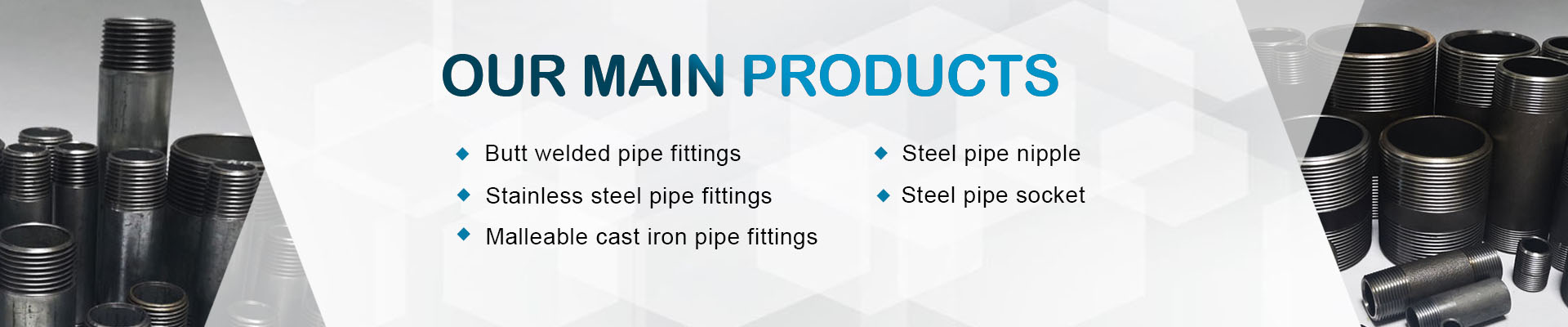

Quality Pipe Fittings from Cangzhou Hongxin

Cangzhou Hongxin is a reputable manufacturer and supplier of pipe fittings in China. We export a wide range of threaded pipe fittings, including galvanized pipe nipples and couplings (made from carbon steel), black pipe nipples and couplings, and stainless steel pipe nipples and couplings. Additionally, we offer stainless steel threaded pipe fittings.

If you need specialized or custom-sized pipe fittings, please do not hesitate to contact us today or fill out our request for quote form online.