| Standard | ASTMA234,ASTM A420,ANSI B16.9/B16.28/B16.25,ASME B16.9 |

| JIS B2311-1997/2312, JIS B2311/B2312, DIN 2605-1/2617/2615 | |

| GB 12459—99,EN Standard etc. | |

| Size | 1/8″—6″ |

| Thickness | SCH10, SCH20, SCH30, STD, SCH40, SCH60,XS, SCH80, SCH100, SCH120, SCH140, SCH160, XXS etc are vailable |

| Material | stainless steel, carbon steel, alloy steel |

| Stainless steel(ASTM A403 WP304,304L,316,316L,321. 1Cr18Ni9Ti, 00Cr19Ni10,00Cr17Ni14Mo2, etc) | |

| Carbon steel(ASTM A234WPB,,A234WPC,A420WPL6. 20#,Q235,10#,20#,A3, Q235A, 20G,16Mn, etc) | |

| Alloy steel(ASTM A234 WP12,WP11,WP22,WP5,WP9,WP91,16MnR, Cr5Mo, 12Cr1MoV, 10CrMo910,15CrMo, 12Cr2Mo1, etc) | |

| Connection | Butt welding |

| Socket welding | |

| Threaded | |

| Surface | stainless steel: Polishing, Sand-blasting |

| carbon steel/alloy steel | |

| Black painting, varnish paint, anti rust oil, hot galvanized, cold | |

| galvanized, 3PE,etc | |

| certificate | ISO 9001 |

| Package | Plastic film, wooden cases ,wooden pallet |

Product Overview

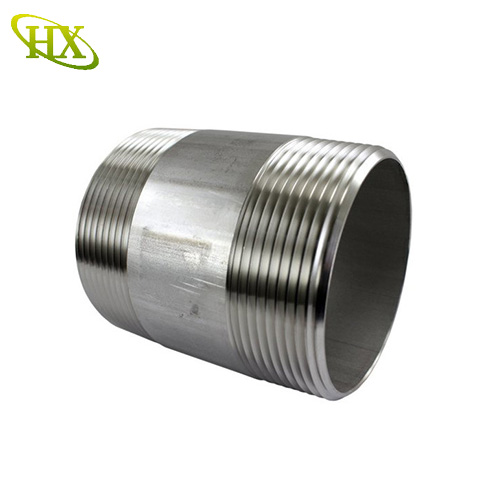

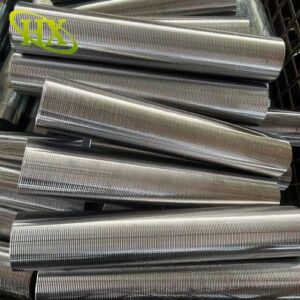

A stainless steel pipe nipple is a short, threaded pipe connector used to join two pipes or fittings in industrial, commercial, and residential plumbing systems. Made from high-quality 304 or 316 stainless steel, these nipples offer excellent corrosion resistance, strength, and longevity, making them ideal for harsh environments.

Key Features & Benefits

Premium Stainless Steel – Made from 304 (18-8) or 316 (marine-grade) stainless steel for superior rust and chemical resistance.

High-Pressure & Temperature Resistance – Suitable for steam, oil, gas, and hydraulic systems.

Seamless & Welded Options – Available in seamless (for high-pressure) or welded (cost-effective) designs.

Precision Threading – NPT (National Pipe Taper) or BSP (British Standard Pipe) threads for secure, leak-proof connections.

Versatile Applications – Used in water supply, chemical processing, food & beverage, and marine industries.

Common Applications

– Oil & Gas Pipelines – Resistant to harsh chemicals and high pressures.

– Water Treatment Plants – Prevents rust and scaling in potable water systems.

– Food & Beverage Industry – Hygienic, non-reactive, and easy to clean.

– Marine & Offshore – 316 stainless steel resists saltwater corrosion.

– HVAC & Fire Protection Systems – Reliable performance in extreme temperatures.

Available Sizes & Specifications

– Size Range: 1/8″ to 4″ (DN6 to DN100)

– Schedule: SCH10, SCH40, SCH80 (standard & heavy-duty)

– Thread Types: NPT, BSPP, BSPT

– Standards: ASTM A312, ASME B36.19, DIN, ISO

Why Choose Our Stainless Steel Pipe Nipples?

Long-Lasting Durability – Resists pitting, cracking, and oxidation.

Leak-Proof Performance – Precision-cut threads ensure tight seals.

Wide Compatibility – Works with most pipe fittings and flanges.

Certified Quality – Meets ASTM, ASME, and ISO standards.

Order Now for Reliable Pipe Connections!

Upgrade your piping system with high-quality stainless steel pipe nipples – trusted by industries worldwide. Contact us for bulk orders and custom sizes!

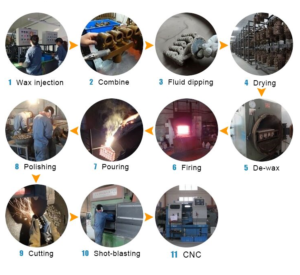

Product process

1. Do the product mold, wax mould processing.

2. The combination type wax.

3. To set a good wax mucilage, 4-5 times

4. Dry processing.

5. In the heart of the dewaxing kettle wax processing.

6. In the high temperature furnace roasting.

7. The key casting operations.

8. The product grinding.

9. The product cut apart.

10. for blasting processing.

11. CNC machining thread.